Fully Automated, Stand-Alone Flowering Tent

3 × 1.5 × 2.4 m

Specs:

- Size: 3 × 1.5 × 2.4 m

- Light: 2 × Mars Hydro FC-E 6500 (730 watt)

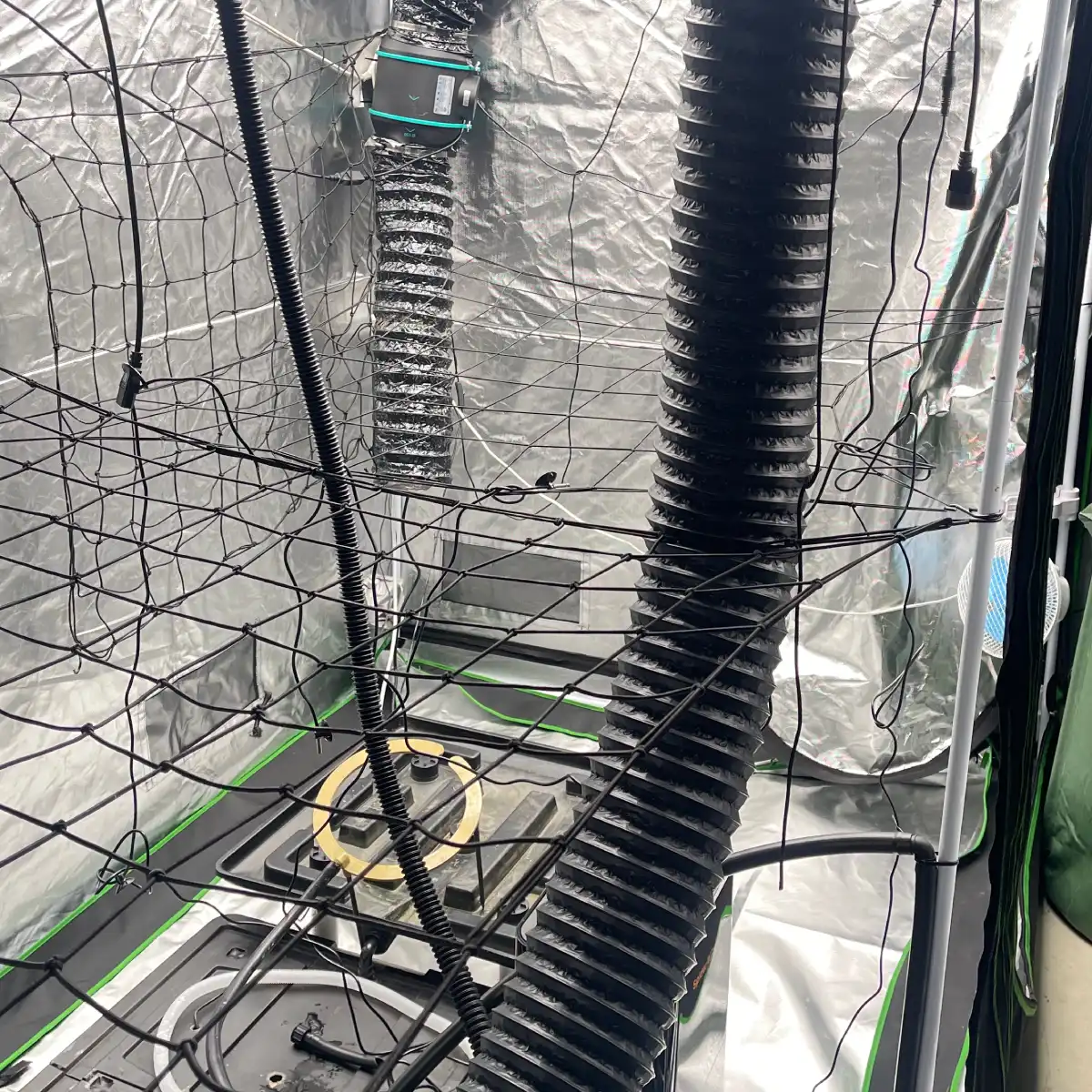

- Ventilation:

- Intake: 1X Mars Hydro Digital 6″ 1X Vivosun S6 with Automotive Air Filter

- Exhaust: 1X Vivosun S6

- Climate Control:

- Arlec 2.6kw Portable Air conditioner (grid connect wifi controller)

- Spider Farmer Humidifier 6L (Automatic with external sensor)

- Spider Farmer Dehumidifier 32 Pint (Automatic with external sensor)

- Arlec 1700W Ceramic Heater (Inkbird Wifi controller)

- Circulation Fans

- 5X 6″ clip on fans

- Mars Hydro Ifresh 6″ ducted from the AC vent to the roof (Same AC wifi controller)

- Irrigation – Closed Loop (Two Tanks):

- Main tank: SeaHawk Hydro tank, 200 L (outside the tent)

- Reservoir: 65 L storage container (inside the tent)

- Main pump: Brushless water pump, 5 m head, 1100 L/h

- Reservoir pump: Brushless water pump, 5 m head, 1100 L/h

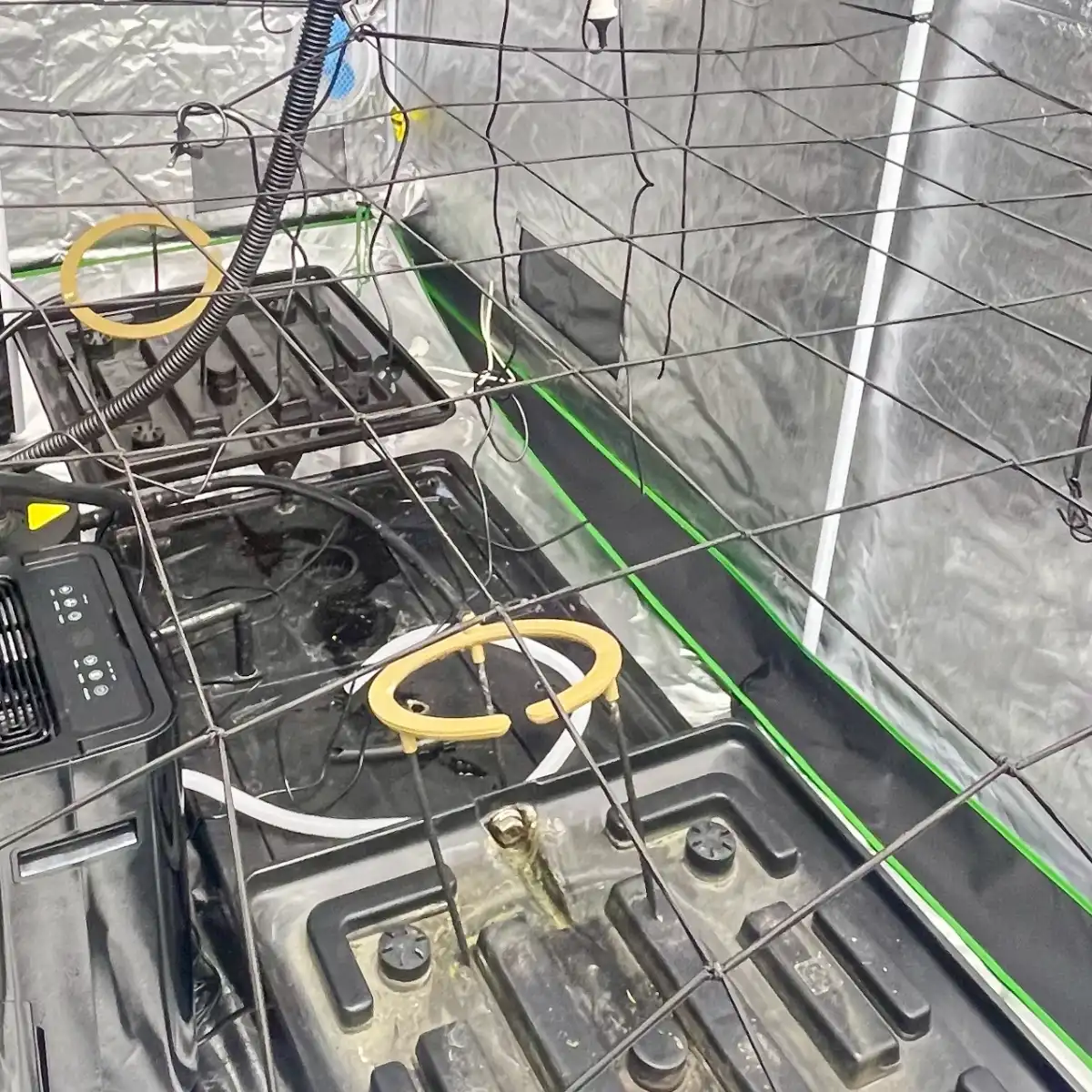

- Plant stand: 2 × The Bucket Company 22″ stands with extended legs

- ScrOG net: 4 × 120X120 elastic net

- Plumbing: Closed-loop irrigation and drainage with halo ring feeders

- Control: Grid Connect WiFi controllers for automatic feeding and recycling

This 3 × 1.5 × 2.4 m tent was built as a compact, high-control flowering space designed for two large plants. Lighting was delivered by two Mars Hydro FC-E 6500 fixtures (730 W each), giving full, intense coverage across the narrow footprint.

Fresh air entered through two Mars Hydro iFresh 6″ intake fans fitted with automotive filters, while a single Vivosun S6 handled extraction. The tent’s climate stability relied on a 2.6 kW Arlec portable air conditioner with WiFi control, supported by a Spider Farmer 6 L humidifier and a Spider Farmer 32-pint dehumidifier—both using external sensors for accurate environmental response. An Arlec 1700 W ceramic heater on an Inkbird WiFi controller maintained temperature during colder periods. A Mars Hydro 6″ duct was also connected to the AC vent and routed to the tent roof to improve airflow distribution.

Air movement within the tent was managed by five 6″ clip-on fans positioned to keep the canopy and understory constantly circulating.

The irrigation system was a closed-loop design running from a 200 L SeaHawk main tank outside the tent and a 65 L internal reservoir. Both pumps were 1100 L/h brushless units with a 5 m head height. Two Bucket Company 22″ stands with extended legs supported the plants, with halo ring feeders ensuring even nutrient delivery. All drainage was captured and recycled automatically.

Four elastic 120 × 120 cm ScrOG nets provided structured canopy shaping for maximum light efficiency in the limited space.

Feeding cycles, recycling, and environmental equipment were all controlled using Grid Connect WiFi devices, allowing the tent to operate independently and be monitored or adjusted remotely.