Fully Automated, Stand-Alone Flowering Tent

3 × 3 × 2.4 m

Specs:

- Size: 3 × 3 × 2.4 m

- Light: 4 × 480w LED Lights

- Ventilation:

- Intake: 2X Mars Hydro Ifresh 6″ with Automotive Air Filter

- Exhaust: 2X Vivosun S6

- Climate Control:

- Arlec portable WiFi AC, 16,000 BTU, reverse cycle (heating & cooling)

- Vivosun H19 Intelligent Humidifier

- Circulation Fans

- 8X 6″ clip on fans

- Irrigation – Closed Loop (Two Tanks):

- Main tank: SeaHawk Hydro tank, 200 L (outside the tent)

- Reservoir: 100 L storage container (inside the tent)

- Main pump: Brushless water pump, 5 m head, 1100 L/h

- Reservoir pump: Brushless water pump, 5 m head, 1100 L/h

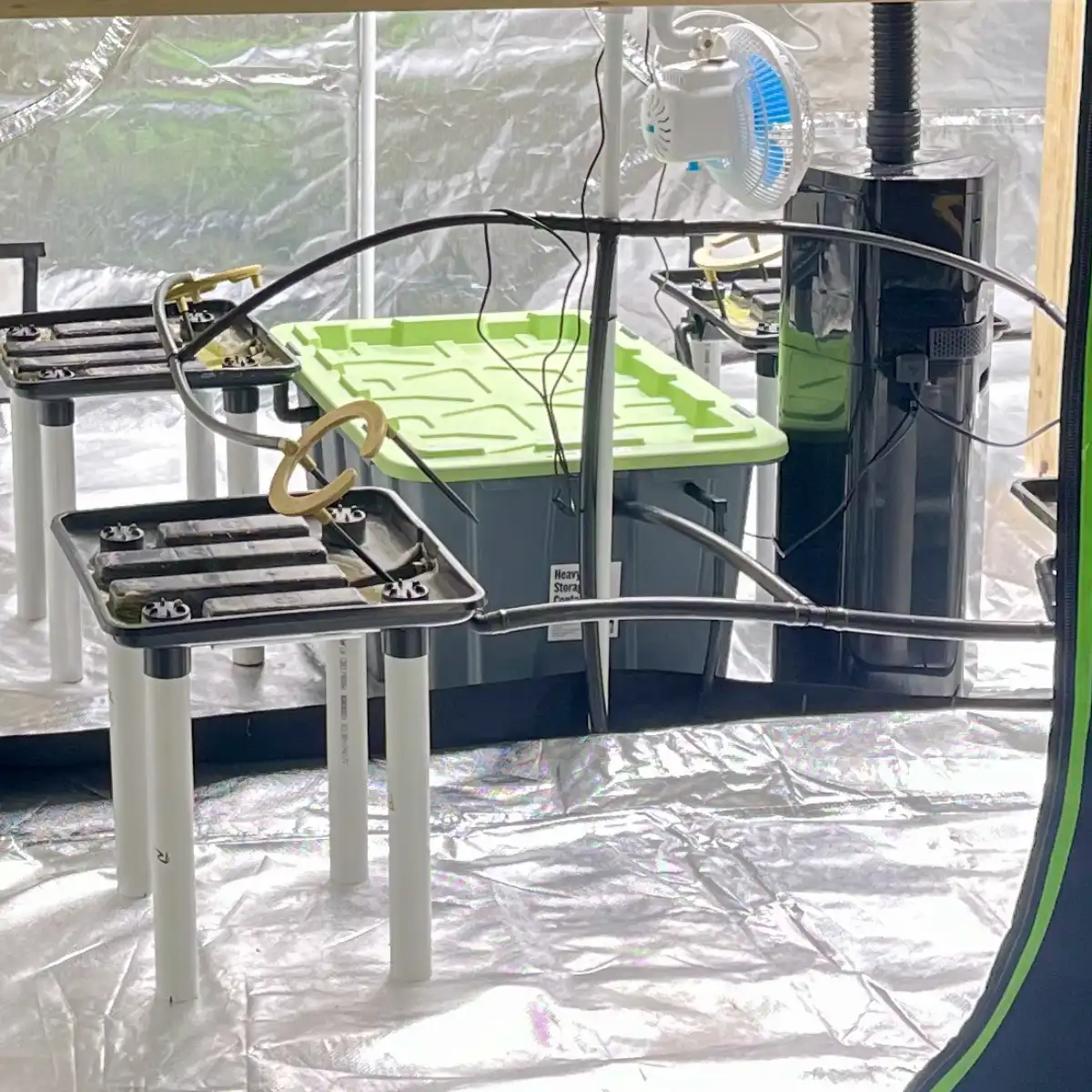

- Plant stand: 4 × The Bucket Company 15″ stands with extended legs

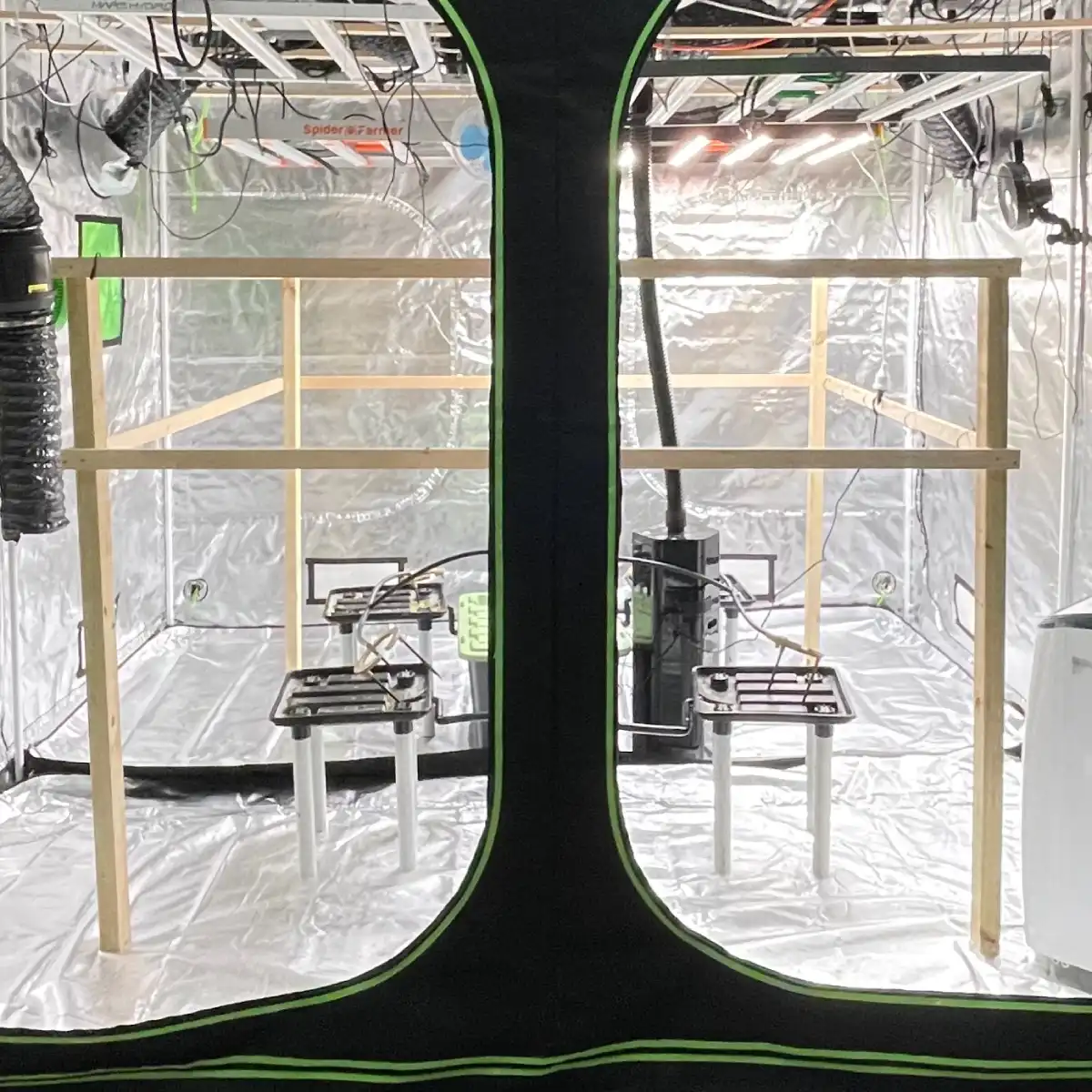

- ScrOG net: 2 × 2 × 2 m plastic nets on a wooden frame with 40 cm spacing

- Plumbing: Closed-loop irrigation and drainage with halo ring feeders

- Control: Grid Connect WiFi controllers for automatic feeding and recycling

This 3 × 3 × 2.4 m flowering tent was built as a compact, fully automated system designed for four high-performance plants. The lighting setup used four 480 W LED fixtures to deliver strong, even canopy coverage across the entire footprint.

Fresh air was supplied through two Mars Hydro iFresh 6″ intake fans fitted with automotive filters, while two Vivosun S6 units handled extraction. Climate stability came from an Arlec 16,000 BTU WiFi AC running in reverse-cycle mode, supported by a Vivosun H19 intelligent humidifier to keep temperature and humidity within range throughout the grow.

Irrigation was a full closed-loop system built around a 200 L SeaHawk main tank outside the tent and a 100 L internal reservoir. Both the main pump and reservoir pump were 5 m head, 1100 L/h brushless units, feeding four Bucket Company 15″ stands fitted with extended legs for easy drainage and runoff collection. Halo ring feeders ensured even distribution across all pots, with WiFi controllers managing feeding cycles and recycling automatically.

A wooden frame held two 2 × 2 m ScrOG nets spaced at 40 cm, allowing structured canopy training in a tight footprint. Internal circulation was handled by eight 6″ clip-on fans positioned to keep airflow moving through and across the canopy.

The result is a small-footprint tent with the same level of automation, climate stability, and irrigation precision as your larger builds—an efficient, high-performance system designed to run independently and consistently.