Fully Automated, Stand-Alone Flowering Tent

6 × 3 × 2.4 m

Specs:

- Size: 6 × 3 × 2.4 m

- Light: 4 × Mars Hydro FC-E1200W

- Ventilation:

- Intake: 3X Mars Hydro Ifresh 6″ with Automotive Air Filter

- Exhaust: 3X Vivosun S6 & 1X Mars Hydro Automatic 6″

- Climate Control:

- Arlec portable WiFi AC, 16,000 BTU, reverse cycle (heating & cooling)

- Euromatic portable air conditioner, 3.5 kW (Grid Connect WiFi control)

- Vivosun H19 Intelligent Humidifier

- Circulation Fans

- 2X Click wall fan 40cm

- 1X Arlec Floor fan 40cm

- Irrigation – Closed Loop (Two Tanks):

- Main tank: SeaHawk Hydro tank, 250 L (outside the tent)

- Reservoir: 100 L storage container (inside the tent)

- Main pump: AQUAPRO AP3000 water feature pump

- Reservoir pump: Brushless water pump, 5 m head, 1100 L/h

- Plant stand: 7 × The Bucket Company 22″ stands with extended legs

- ScrOG net: 2 × 5 × 2 m plastic nets on a wooden frame with 40 cm spacing

- Plumbing: Closed-loop irrigation and drainage with halo ring feeders

- Control: Grid Connect WiFi controllers for automatic feeding and recycling

- Power Dedicated feed from main switchboard:

- 1 × 40 A switch

- 2 × 25 mm cables, 20 m each (separate circuits)

- 2 × Grid Connect WiFi double wall sockets

- 8 × standard double wall sockets

- 1 × 5-pin plug assembly

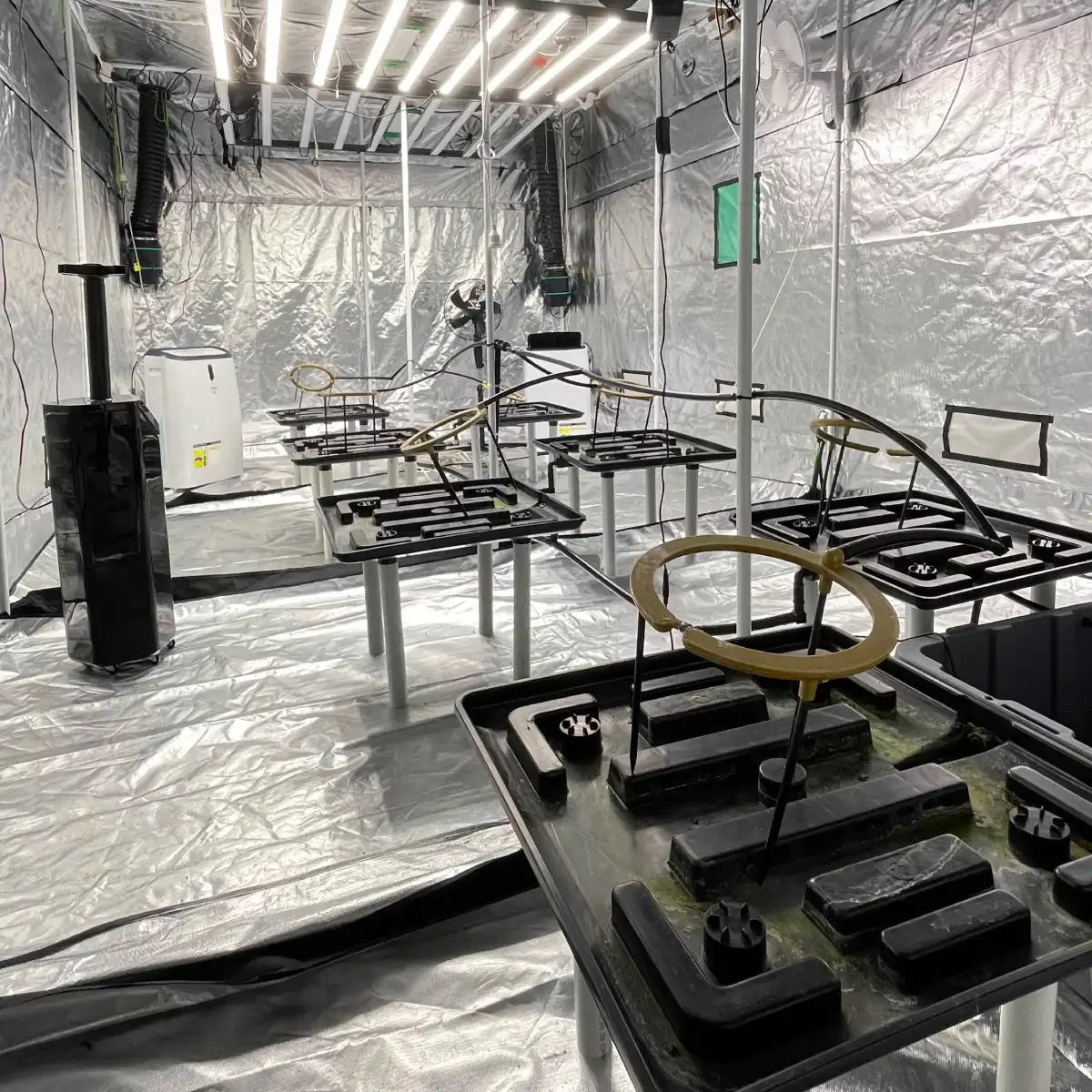

This 6 × 3 × 2.4 m flowering tent was designed as a fully automated, stand-alone system. It ran seven large plants comfortably, with capacity for an eighth if needed. Lighting was provided by four Mars Hydro FC-E1200W fixtures, giving full canopy coverage and enough headroom to push plants hard in late flower.

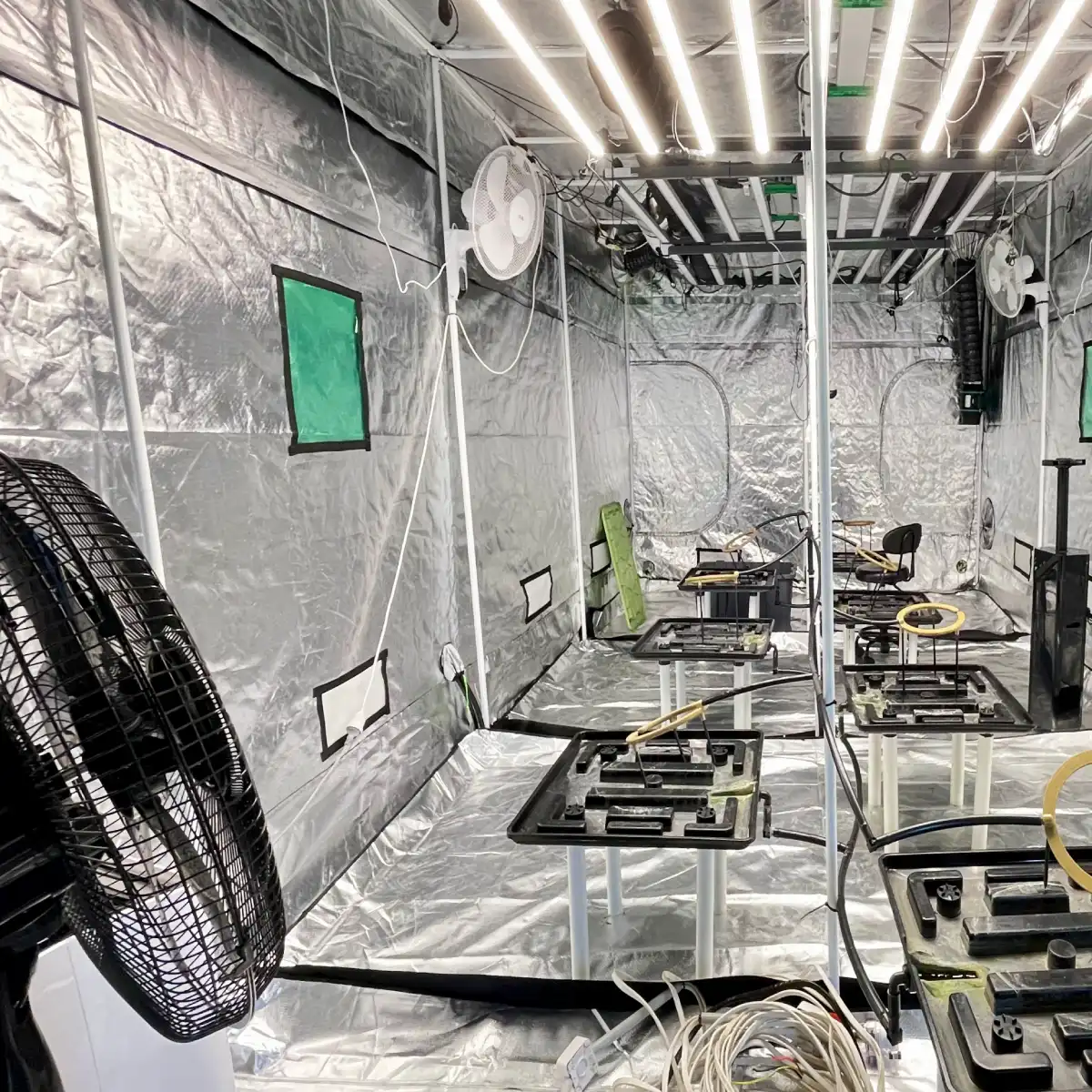

Environment control was completely independent from the rest of the site. Fresh air came through three Mars Hydro iFresh 6″ intake fans with automotive filters, while three Vivosun S6 units and one Mars Hydro 6″ automatic fan handled extraction. Climate was stabilised by an Arlec 16,000 BTU WiFi AC and a 3.5 kW Euromatic portable air conditioner on Grid Connect, supported by a Vivosun H19 intelligent humidifier to keep VPD in range.

The irrigation system was a closed-loop design built around a 250 L SeaHawk main tank outside the tent and a 100 L internal reservoir. Seven Bucket Company 22″ stands with extended legs sat over the plumbing so runoff could be captured, pumped back, and reused. An AQUAPRO AP3000 managed main flow, with a secondary brushless pump (5 m, 1100 L/h) in the reservoir. Feeding, recycling, and scheduling were all controlled via WiFi, allowing precise monitoring of plant uptake and nutrient use.

Air movement inside the tent came from two 40 cm Click wall fans and a 40 cm Arlec floor fan.

A 5 × 2 m wooden frame holding twin ScrOG nets at 40 cm spacing for structured canopy management.

Power was delivered directly from the main switchboard through a 40 A breaker and two 25 mm feeds on separate circuits—one dedicated to lighting and one for all auxiliary equipment. Grid Connect WiFi wall sockets and multiple double outlets made the whole system plug-and-play, with a 5-pin plug assembly so the entire tent could be disconnected and moved as a single unit. The full setup was monitored and controlled from a phone.